Complex Ceramic Crucible Assembly for Thermogravimetric Analysis

In high-end metrology and scientific research, measurement accuracy critically depends on the quality of the components used within the system. Especially in research and quality control, even minor inaccuracies in mass measurement can lead to misleading data or uncontrolled fluctuations in product quality.

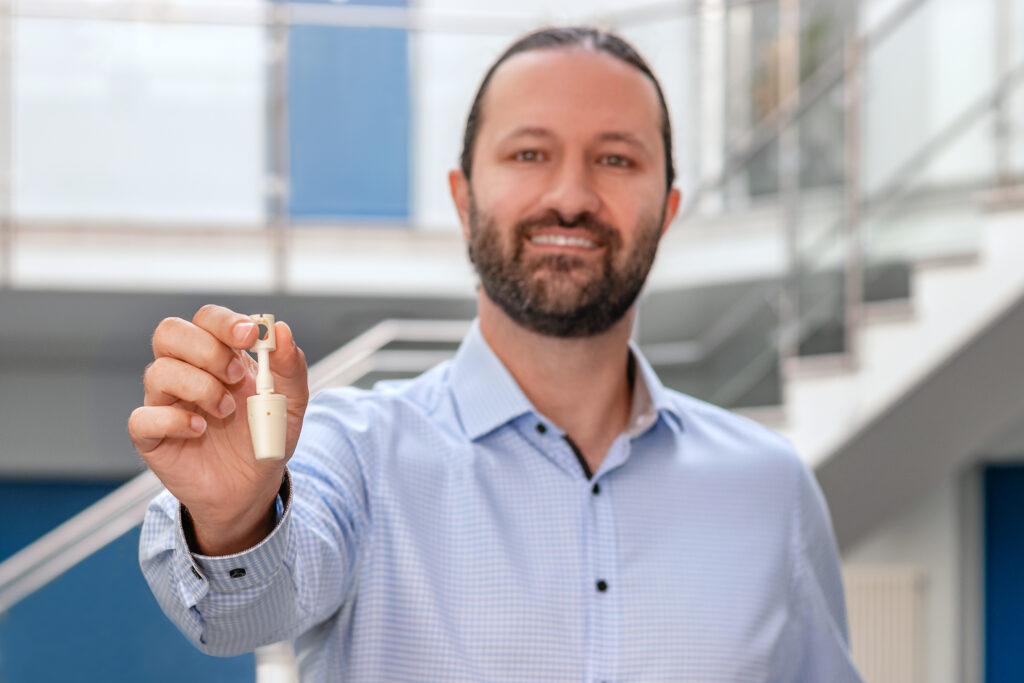

For a client in laboratory analytics, we developed and produced a complex ceramic crucible assembly made of high-purity alumina. This solution was specifically designed for ultra-precise absorption measurements under thermogravimetric analysis (TGA) conditions. The assembly consists of a crucible, lid, and suspension rod. The rod is available in two lengths for compatibility with different furnace designs, and the crucible can hold up to 25 g of sample material.

A key feature is the contactless magnetic suspension coupling, which isolates the weighing system from mechanical loads. This decoupling allows precise zero-point calibration and drift-compensated long-term measurement. With this setup, mass changes as small as 1 µg can be measured—at temperatures up to 1500 °C and pressures up to 50 bar.

Why Ceramic? Why 3D Printing?

Ceramic materials are ideal for demanding laboratory environments. They remain chemically inert and dimensionally stable even under extreme temperatures and corrosive atmospheres—precisely the conditions found in gravimetric analysis. Their inertness ensures that even at high temperatures, the material won’t interfere with sensitive measurement results.

While standard crucibles are often pressed or CNC machined due to their simple geometry, ceramic 3D printing becomes the preferred method when performance benefits can be gained from complex geometries.

Key reasons we used ceramic 3D printing in this project:

-

The crucible design includes internal bores, fine microholes, and thin wall sections that are difficult or impossible to realize using pressing or CNC.

-

Redesigning the part for conventional manufacturing would have compromised its function.

-

These parts are custom-made in low volumes. Compared to CNC setups, 3D printing provides faster turnaround and lower cost for one-off or small-batch production.

Explore more real-world ceramic applications

Visit hilgenberg-ceramics.com/news to discover how our customers benefit from ceramic 3D printing in prototype and low-volume manufacturing.

Have a challenge of your own? Contact us by email or phone – we’re ready to support your unique application.