Bricks Become High-Tech Components

Modern bricks must meet increasingly demanding requirements. Rising energy costs and stricter building codes are pushing the limits of thermal insulation. In addition to thermal performance, key properties include sound insulation and mechanical stability. Thanks to continuous innovation, today’s bricks are no longer just fired clay—they’re high-tech products. Naturally, expectations for dimensional accuracy are rising as well.

The ongoing push for better sound insulation is forcing manufacturers to create finer cavities and thinner walls, often using sophisticated internal structures to diffuse sound—similar to a muffler. This is achieved using a sound-absorbing wall inside the brick, a concept known as functionalization.

It All Comes Down to the Extrusion Tool

Bricks are typically produced using extrusion, where clay is pressed through a die. The brick’s internal void geometry is defined by placeholders known as extrusion cores. As clay flows around these cores inside the die, it leaves behind voids that form the final brick structure of ribs and cavities.

Achieving the exact cavity layout requires meticulous die design. As complexity increases, the clay flow inside the die can become inhomogeneous, leading to flow instabilities, turbulence, and unwanted textures. Ideally, each extrusion core must have a custom geometry to optimize flow at its specific position in the die.

Perfect Extrusion Tools Thanks to Ceramic 3D Printing

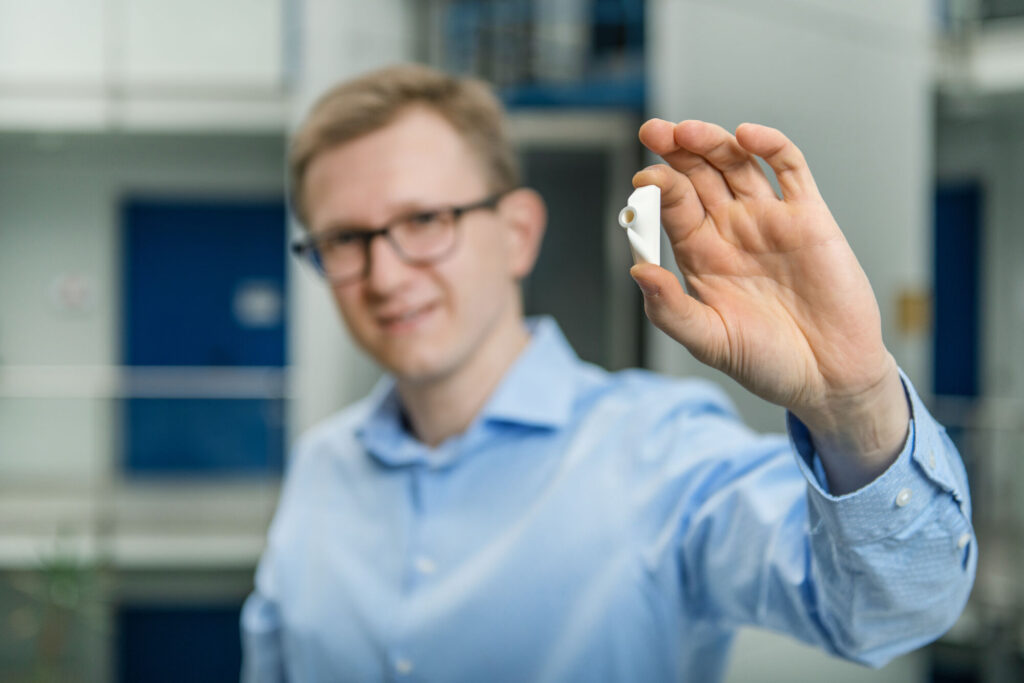

In a development project with our partner Mein Ziegelhaus—a research hub of the German brick manufacturing consortium—we used ceramic 3D printing to produce topology-optimized extrusion cores from high-purity aluminum oxide (Al₂O₃).

Within just a few weeks, we enabled the development of entirely new brick geometries—faster and at much lower cost than conventional methods. The printed cores, as hard and wear-resistant as sapphire, significantly outperformed traditional steel tools in terms of durability.

Ceramic 3D Printing Has Even More to Offer

Our project demonstrates that 3D-printed ceramic extrusion tools enable faster, more innovative, and ultimately more cost-effective brick manufacturing compared to traditional steel tools. These insights pave the way for even more optimization in the brick industry. And thanks to 3D printing, future adjustments can be implemented quickly and flexibly.

Looking Ahead

We believe that the flexibility of ceramic 3D printing offers valuable benefits for many other industries and applications. We’ll continue sharing examples regularly on our website at hilgenberg-ceramics.com/news.

Do you have questions about this case study—or are you looking to explore ceramic 3D printing for your own application? Feel free to reach out to us by phone or email.