Project Background

MYRRHA is the name of an ambitious European project aimed at developing the next generation of clean and safe nuclear power plants. With a budget of around €1.6 billion, a novel research reactor is set to be built in Mol, Belgium by 2036. It promises three fundamental improvements over current reactor technology:

-

Transmutation of nuclear waste: This reduces long-term radioactivity by a factor of 1,000, cutting storage requirements from 300,000 years down to just 300.

-

Inherent safety: The reactor core design enables automatic shutdown during system failure, eliminating the risk of meltdown scenarios.

-

Medical isotope production: Besides its research functions, the reactor will also produce critical radioisotopes for cancer diagnosis and therapy.

During the current design phase, the Institute for Thermal Energy Technology and Safety (ITES) at the Karlsruhe Institute of Technology (KIT) is evaluating the reliability of thermohydraulic components inside the Belgian research reactor. One key focus is on the hexagonal fuel rod bundles located in the reactor core. These are cooled by a flowing mixture of lead and bismuth. However, if lead oxide or other foreign particles accumulate in the liquid metal, blockages can form that disrupt heat removal from the core.

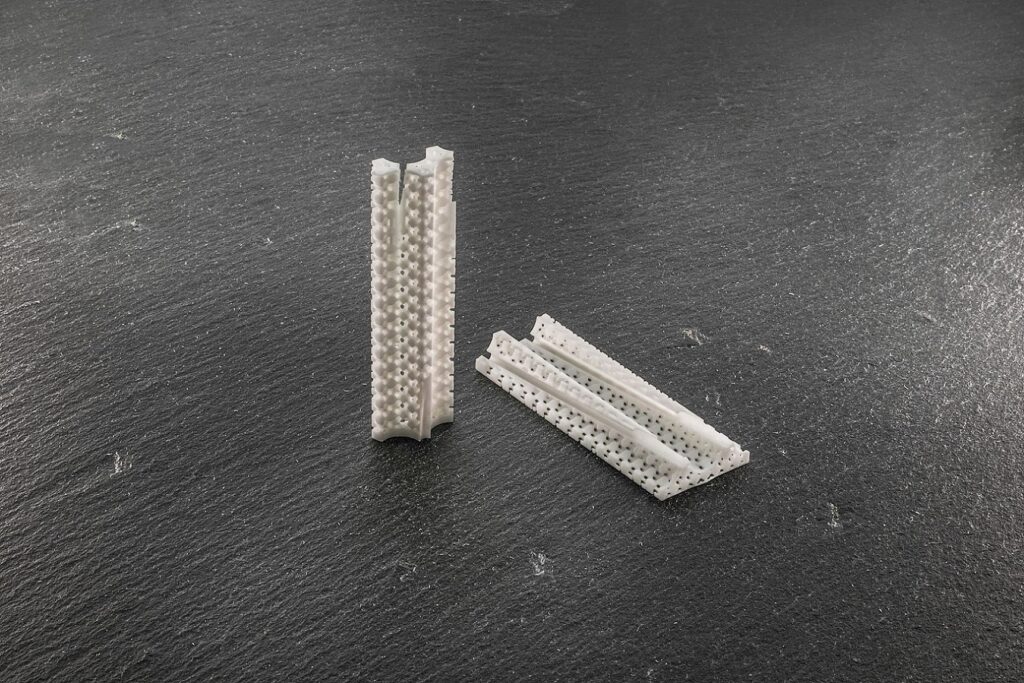

To better simulate such blockages, Hilgenberg Ceramics worked with ITES to develop a ceramic flow restrictor that mimics real-world obstructions. This enables more accurate CFD simulations (Computational Fluid Dynamics), helping engineers optimize the cooling system. The component must withstand extreme conditions: temperatures between 200°C and 450°C, fluid velocities up to 2 m/s in molten metal, and tightly controlled geometry in the millimeter range.

Why Use 3D-Printed Ceramics?

In earlier experiments, wire mesh inserts made of metal were used to simulate blockages. However, they proved inadequate in replicating the flow behavior realistically. A new approach using 3D-printed zirconia ceramics (ZrO₂) offered several distinct advantages:

-

Thermal and chemical resistance to withstand the harsh test environment

-

Low thermal conductivity, closely matching that of oxide blockages

-

Highly detailed geometry, replicating the porous structures of real oxides for accurate simulation of flow resistance

-

Design flexibility, enabling quick iteration and geometry refinement during the development process

These features make ceramic 3D printing a valuable tool for modeling and validating reactor behavior long before physical construction.

Engineering Challenges in Ceramic 3D Printing

To realistically represent a blockage caused by metal oxides, the printed ceramic part must introduce a comparable flow resistance. This is achieved through dense packing and narrow channels that restrict the movement of the lead-bismuth coolant.

One key requirement: the flow resistance must be isotropic, meaning equally distributed across the surface. If not, the molten metal would take the path of least resistance, invalidating the results.

3D printing is uniquely capable of producing such complex structures, but it presents its own set of challenges:

-

Printability and cleanability: Highly compact structures are difficult to clean after sintering, requiring careful design

-

Custom geometry: Standard lattice structures (like gyroid or diamond grids) don’t offer isotropic flow. A new structure was specifically developed to replicate oxide buildup more realistically

-

High complexity with thin connections: This increases the risk of defects. Customized printing parameters are necessary to ensure reliable manufacturing

Outlook

The current test series shows that the printed geometry mimics the expected oxide blockage behavior well. Further refinements will improve accuracy, but even at this stage, the ceramic flow restrictor meets the requirements and plays an essential role in the safe design of the MYRRHA reactor.

Want to learn more? We regularly share real-world applications of ceramic 3D printing at

www.hilgenberg-ceramics.com/news.

Feel free to reach out to us for more information — we look forward to hearing from you!

For further insights into our partner’s work at KIT, visit

www.ites.kit.edu