Discover Our Range of Services

Engineering for Advanced Ceramics

Designing with engineered ceramics requires a unique approach that differs significantly from conventional manufacturing with metals or plastics. Whether you come to us with a challenge, an idea, or a fully developed design, we provide tailored engineering solutions to turn your vision into reality.

Our process combines deep expertise with practical know-how:

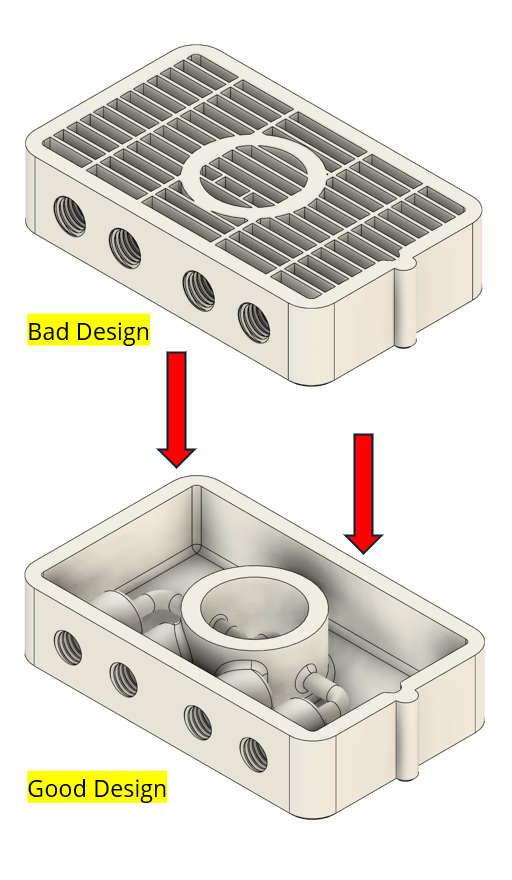

- Ceramic-Specific Design Optimization:

Advanced ceramics shrink by up to 30% during sintering, requiring precise design adjustments to ensure defect-free parts. We work closely with you from the start to align your design with the most suitable manufacturing process, be it additive 3D printing or subtractive milling and grinding. - Balancing Performance and Cost:

The best designs are not only fit for their application but also optimized for efficient and cost-effective manufacturing. Our team helps you achieve this balance, maximizing value without compromising quality. - Proven Expertise:

With over a thousand successful projects in Germany and the U.S., we know what works—and how to make it work.

-> Learn more about Ceramic Design Optimization and tailored solutions

Additive Manufacturing Service of Advanced Ceramics

Our 3D printing service leverages cutting-edge Admatec

technology, which uses UV light to cure a ceramic slurry into a green body.

This green body is then debinded and sintered, producing a fully dense,

high-precision engineered ceramic component.

Our standard materials, always in stock, include:

- Alumina (Al₂O₃) – extremely hard, wear-resistant, dielectric

- Zirconia (ZrO₂) – mechanically tough, very smooth surface

When to Choose 3D Printing for Your Ceramic Parts:

- Your parts are smaller than a fist size.

- Wall thickness ranges between 0.02–0.2 inches (0.5–5 mm).

- Low production quantities are required.

- You expect multiple design iterations during development.

- Complex geometries, like gyroid structures or intricate tubing, are essential to

your design. - Standard lead time: 5 weeks; Express options: 3 weeks.

- Get an instant quote using our online pricing tool.

-> Learn more about Ceramic 3D Printing and its unique possibilities

Milling of Ceramics

Milling of Ceramics, often called Green Machining, is a subtractive process used to mill isostatically dry-pressed (green) ceramic bodies. After machining, parts are debinded and sintered, shrinking approximately 20% while achieving full density.

Our standard materials, always in stock, include:

- Alumina (Al₂O₃) – extremely hard, wear-resistant, dielectric

- Zirconia (ZrO₂) – mechanically tough, very smooth surface

Advantages of Milling Over 3D Printing:

- Generally better for parts larger than a fist size.

- Better suited for medium production runs of 20+ parts.

- Cost savings can be achieved for higher quantities, even with setup costs of $200–700 per part.

- Ideal for wall thicknesses above 5 mm and simpler geometries.

- Typically offers better mechanical strength than 3D-printed parts.

- Standard lead time: 5 weeks; Express options: 3 weeks.

-> Learn more about Ceramic Milling and real-world applications

Grinding of Ceramics

Grinding, also known as hard machining, utilizes diamond tooling to achieve the tight tolerances

required for applications like precision fittings.

Our In-House Capabilities Include:

- Tolerances on parts in production using 5-axis machining: ±0.0004 inches (±10 µm)

- Tolerances on prototypes using 5-axis machining: ±0.0002 inches (±5 µm)

- Mirror polishing on freeform surfaces up to Ra 8 µin (Ra 0.2 µm)

Standard materials always in stock include:

- Alumina (Al₂O₃) – extremely hard, wear-resistant, dielectric

- Zirconia (ZrO₂) – mechanically tough, very smooth surface

On request, we can process:

- Silicon Nitride (Si₃N₄) – thermal shock resistant, tough, very hard

- Silicon Carbide (SiC) – excellent thermal conductor, extremely hard

- hBN-TiB2 – electrically conductive, non-wettable by liquid metals

- Ceramic Refractory Materials – large parts, porous, high-temp. application

- Shapal

- Macor

-> Discover capabilities and applicatons of Ceramic Grinding

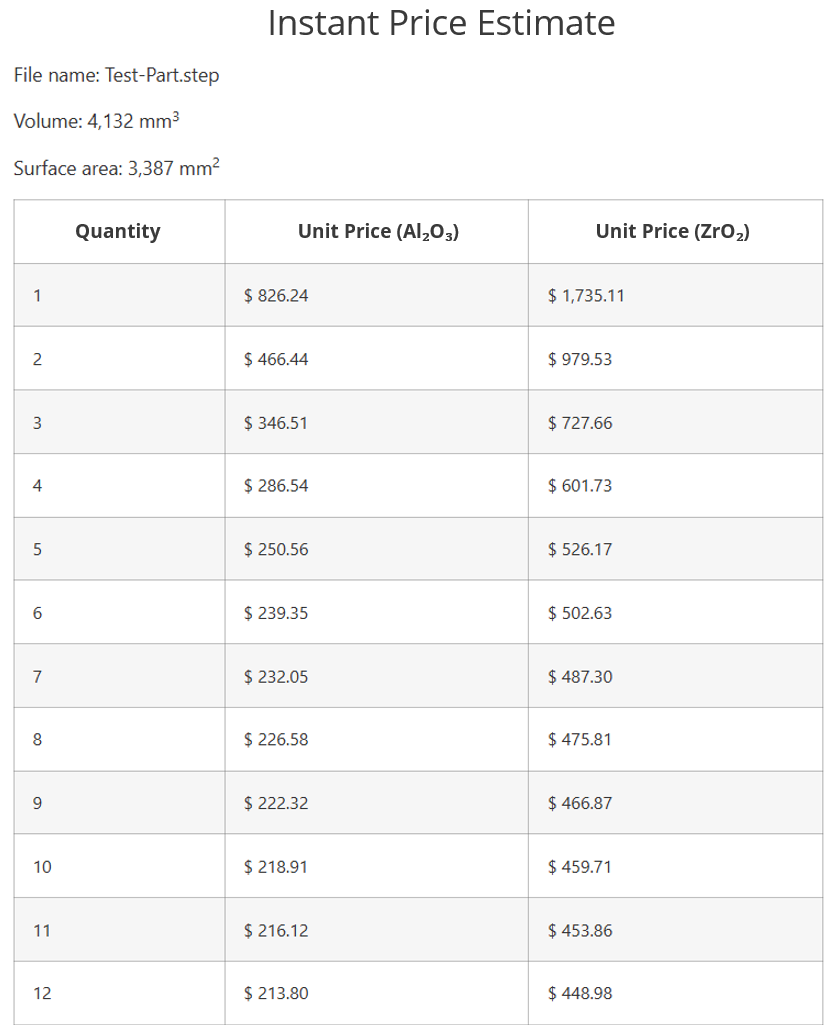

Upload Your CAD File for an Instant Quote

Save time and receive an instant pricing for 3D printing advanced ceramic parts.

Simply upload your CAD file (.STEP or .STL, max. 40 MB) to our online pricing tool, and get an instant quote for 1–50 pieces in Alumina (Al₂O₃) and Zirconia (ZrO₂).

With just one upload, you’ll get:

- Pricing for multiple quantities and both materials at a glance.

- A hassle-free way to plan your project budget and explore cost-effective

options. - The flexibility to compare variations of your design or different quantities

in seconds, helping you find the financial sweet spot for your project.

Hermetic Ceramic-Metal Joints

Using advanced active brazing techniques, we create hermetic joints between Alumina (Al₂O₃) and metals such as stainless steel 316L, titanium grade 2, and pure copper. These custom-made parts are designed to meet your specifications and are suitable for applications up to 752°F (400°C).

Typical Applications:

- Weldable or flange-mounted vacuum ceramic breaks

- Ceramic-to-metal feedthroughs

- Hermetic insulators