Grinding of Ceramics

Explore our precision grinding capabilities for custom-made advanced ceramic parts.

Our Process for Hard Grinding of Advanced Ceramics

Hard grinding of ceramics is a subtractive manufacturing process in which material is precisely removed from fully sintered ceramic components using diamond tooling. This method achieves unparalleled dimensional accuracy and superior surface quality, essential for high-performance ceramic applications. Though material removal rates are relatively low – leading to higher costs – the process yields exceptional precision: ±10 µm for production runs and ±5 µm for prototypes.

Materials for Ceramic Grinding:

We primarily grind sintered ceramic parts originating from our own 3D printing or green machining processes. Our standard stock materials include: Al₂O₃, ZrO₂, ATZ.

For specialized applications, we also work with more exotic ceramic materials, such as: Yttria, Silicon Nitride, Aluminum Nitride, Silicon Carbide or conductive ceramics (e.g., hBN-TiB2)

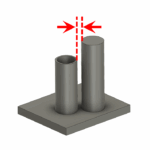

Diamond Tooling Methods

We employ two primary diamond tooling approaches:

I. Diamond-Crystals-Coated Tools

Diamond-crystals-coated tools operate similarly to sandpaper, wherein diamond crystals embedded in the tool surface continuously scratch and remove ceramic material. This method efficiently achieves high-quality surface finishes suitable for most general grinding applications.

II. Monolithic Diamond Tools

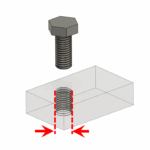

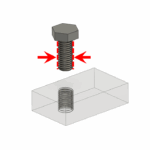

For ultra-high precision and delicate features, we utilize monolithic diamond tools. Unlike coated tools, these tools feature a single solid diamond tip, enabling ultra-smooth surface finishes, enhanced contour accuracy and fabrication of micro-features (holes down to 0.2 mm, threads as small as M1).

This tooling is essential for creating precise micro-channels and extremely small threaded holes, as traditional diamond-crystals-coated tools cannot maintain structural integrity at such small scales. Thus, we rely on monolithic diamond tooling from our trusted suppliers like 6C Tools.

State-of-the-Art Equipment

Grinding operations are performed on advanced GF Mikron 5-axis CNC machining centers equipped with 42,000 RPM spindles. Our machine systems are integrated with an Erowa automation system, ensuring efficient handling, reduced lead times, and consistent quality for small to medium production runs.

High-Precision Polishing

In addition to grinding, we offer advanced 5-axis polishing services. Our polishing process utilizes specialized soft tooling embedded with ultra-fine graded diamond crystals, achieving mirror-polished surface finishes with roughness values as low as Ra=0.01 µm, even on complex freeform geometries.

Real Case Studies

Advantages of Grinding Advanced Ceramics

Precision and Delicacy

The primary reason to choose our CNC grinding service is its unparalleled precision. If your ceramic parts require tolerances tighter than ±100 µm, CNC grinding is the essential solution. This precision extends specifically to ceramic threads, which we strongly recommend grinding when they are designed to handle mechanical loads. CNC grinding reliably achieves ±10 µm for production series and even ±5 µm for prototypes.Exceptional Surface Quality

Another compelling advantage of ceramic grinding is the superior surface finish achievable compared to other ceramic shaping processes. Our capabilities include CNC polishing, which employs soft, diamond-embedded tools instead of rigid grinding tools, allowing us to reach mirror-polished surfaces with roughness values as low as Ra = 0.01 µm.Unlimited Material Options

Our CNC grinding offers unmatched flexibility regarding material choice. Beyond standard advanced ceramics such as Al₂O₃, ZrO₂, we frequently grind specialty materials, including ceramic refractory concretes for precise, contoured sintering setters for metals or foam-structured silicon carbide. This flexibility is especially valuable for prototypes or small production runs, where standard stock materials like various grades of AlN, SiC, Si₃N₄, and popular machinable ceramics such as SHAPAL™ and MACOR® are easily available, significantly reducing setup complexity and cost.Suitable for Mid-Size Series through Automation

Our advanced automation capabilities allow us to efficiently handle big-sized production runs, including batches of several thousand complex ceramic parts requiring tight tolerances. Many customers leverage ceramic injection molding for mass production, and subsequently use our automated CNC grinding service to achieve precise tolerances on these high-volume ceramic components, ensuring consistent quality and cost-effectiveness.Table of Requirements for Grinding of Ceramics

| Visual | Property / Requirement | Value |

|---|---|---|

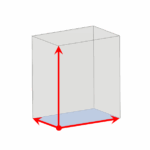

| Max. part size (approx.) | X: 200 mm / Y: 300 mm / Z: 350 mm |

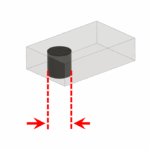

| Min. hole diameter (flat features, approx.) | 0.2 mm |

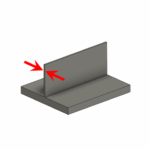

| Minimum wall thickness | 0.1 mm |

| General tolerance (prototypes, testing, small batches) | ±5 µm |

| General tolerance (fully automated production) | ±10 µm |

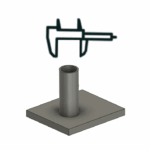

| Smallest grindable internal thread | Al₂O₃ and Si₃N₄ - M2 or larger ZrO₂ - M1 or larger |

| Smallest grindable external thread | M0.5 or larger |

| Surface roughness (flat & freeform) | surface finish down to Ra < 0.01 µm possible (mirror-polished) |

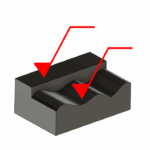

| Minimum feature spacing (deep features) | 4 mm, smaller spacing may result in tapering due to tool deflection |