Milling of Ceramics

Our Process for Green Machined Ceramic Parts

We shape high-density ceramic blocks into precise components using pressing, green machining, and high-temperature sintering.

Pressing:

We typically use ready-to-press (RTP) ceramic powders from suppliers such as Alteo, Almatis, Nabaltec, or Tosoh. For exotic materials like Y₂O₃, we formulate custom RTP blends from raw powders.

The powder is either cold isostatically pressed into freeform shapes, or

uniaxially pre-pressed into flat ceramic bodies, then further densified through cold isostatic pressing. In both cases, we apply up to 300 MPa (45,000 PSI), a key factor for achieving excellent mechanical properties after sintering.

Machining:

After pressing, we carefully prepare a CAD/CAM setup based on your specific part geometry. The green ceramic bodies are then milled on our high-precision, 5-axis CNC machines from Roeders TEC, featuring spindles with speeds up to 42,000 RPM. These specialized machines are engineered for dry, abrasive machining environments, ensuring tight dimensional tolerances, efficient material removal, and exceptional surface quality, even for highly complex ceramic geometries.

Debinding and Sintering:

After machining, ceramic parts undergo thermal debinding, where organic binders are gradually removed at controlled temperatures. This careful process prevents cracking or deformation. Final sintering typically takes place in air at temperatures up to 1650 °C (2250 °F). For specific materials like Y₂O₃, we utilize a hydrogen atmosphere during sintering to optimize the microstructure and ceramic quality.

Real Case Studies

Advantages of Milling of Ceramics

Optimal for Parts Larger Than a Fist

Green machining is a subtractive manufacturing method, meaning costs don’t escalate dramatically as part size increases. Unlike 3D printing, which builds parts layer by layer, consuming extensive machine time, milling efficiently removes excess material from pressed ceramic blanks, keeping production cost-effective for larger components.Better Suited for Medium Production Runs (20+ Parts)

Initial setup, including CAD/CAM programming, typically incurs a one-time cost of around $200–$700 per part. However, the milling process itself is highly efficient, leveraging rapid axis movements and a high-speed spindle (42,000 RPM). With every additional part produced, the per-unit cost drops significantly compared to additive methods, making milling economically attractive for series production.Ideal for Wall Thicknesses Above 5 mm

Our pressed ceramic powders usually contain less than 4% organic binder, often even binder-free. This low binder content significantly streamlines the debinding process compared to 3D printing or injection molding, where binders constitute nearly 20% of the mass. Thick-walled parts (>5 mm) are thus easily achievable without the risk of structural damage caused by internal gas pressure buildup during binder burnout.Superior Mechanical Strength Compared to 3D-Printed Parts

The mechanical strength of ceramics greatly depends on microstructural homogeneity. Our cold isostatic pressing at pressures up to 300 MPa (45,000 PSI) ensures exceptionally uniform compaction, virtually eliminating voids or inconsistencies and delivering the highest possible mechanical integrity in finished components.Extensive Material Freedom

We can process virtually any available ceramic powder. With trusted suppliers like Alteo, Almatis, Nabaltec, or Tosoh, our standard materials—Al₂O₃, ZrO₂, and ZTA—are consistently in stock, either as raw powders or pressed preforms. Additionally, we custom-formulate ready-to-press blends for exotic ceramics such as Y₂O₃, AlN, SiC, and Si₃N₄, ensuring broad flexibility tailored precisely to your requirements. Our standard U.S. lead time is typically 5 weeks for first-time orders. For subsequent repeat orders, we offer an expedited production option with a rapid 2-week turnaround, allowing streamlined and predictable supply chain management.Adequate Precision for Most Applications

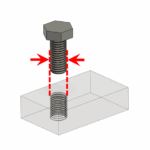

Green machining precision is approximately ±10 µm, although a typical 20% shrinkage during sintering introduces slight distortion. Nevertheless, final dimensional tolerances remain within ±1% (minimum ±0.1 mm), sufficient for most industrial applications. If your application demands exceptionally tight tolerances, we offer precision hard grinding, achieving tolerances down to ±5 µm for critical features.Cost-Efficient Machining of M6 and Larger Threads

While ceramic threads aren’t ideal for high-load fastening, certain applications necessitate their use. Fortunately, our milling allows for cost-effective integration of threads sized M6 and above without requiring additional grinding steps. Smaller or highly loaded threads should ideally be ground post-sintering. For optimal performance and longevity, contact us for recommendations on alternative design approaches.Table of Requirements for Milling of Ceramics

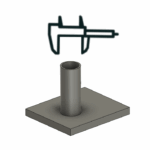

| Visual | Property / Requirement | Value |

|---|---|---|

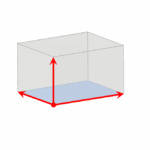

| Max. part size (approx.) | X: 400 mm / Y: 500 mm / Z: 300 mm |

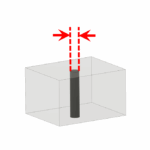

| Smallest drillable hole (approx.) | 0.05 mm |

| Drilled hole: Diameter/Length ratio (approx.) | 1:20 |

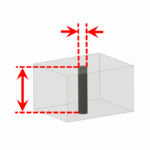

| Minimum wall thickness (approx.) | 0.5 mm |

| General tolerance | ±1 % (minimum ±0.1 mm) |

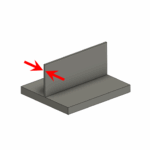

| Smallest usable thread | M6 or larger, smaller threads must be ground |

| Surface roughness (as-fired) | Ra 1.5 |